Packland Fastpack 310mL

The fully automatic Packland Fastpack 310mL / CE case packer packages sealant and grease cartridges in American folding boxes.

The cartridges roll into the machine onto a chain conveyor. After this, the cartridges are collected in a lift, and as a single package pushed into the box. The boxes are pulled out of the magazine and erected automatically. After filling, the box tilts upright and is transported to the box closer. Here the top is closed and both the bottom and top of the box are sealed with 50mm self-adhesive tape.

- Equipped with integrated box magazine, erector and closer

- Compact and ergonomically accessible

- Solid welded steel frame finished with a PU coating

- Complete maual and builte in accordance with CE requirements

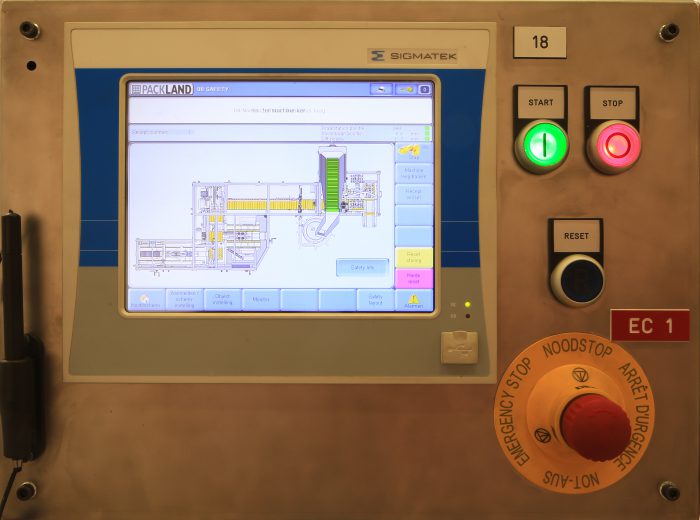

- The machine is PLC controlled and equipped with a touch screen for operation and for displaying error messages

- The touch screen features a USB connection fort eh download and upload of data

- Also, the PLC has a connection for a TCP / IP connection. If required, we can send updates via this link

- Change over into another program is carried out with 5 handwheels with numeric counters, slider bodies and two change parts. The change over time is approximately 10 minutes, and without tools

Technical specifications:

| Packaging speed | approx 100 cartridges per minute, depending on configuration |

| Container types | all standard 310mL cartridges, plastic, aluminium or cardboard |

| Box sizes | 2×3, 3×4, 4×4, 4×5, 4×6, 5×5, others on request |

| Machine dimensions | approx 4000 x 1865 x 1990 mm (L x W x H) without options |

| Compressed air | 6 bar, clean dry air |

| Air consumption | apprx 800L/m |

| Supply voltage | 400V – 3 phase / N / earth 50Hz, others on request |

Options:

- automatic clipping station, up to 60 cartridges per minute

- adding of loose nozzles in the box, up to 100 nozzles per minute

- fixed nozzles

- cartridge orientator for BAR coding or applying a label

- other requirements in consultation