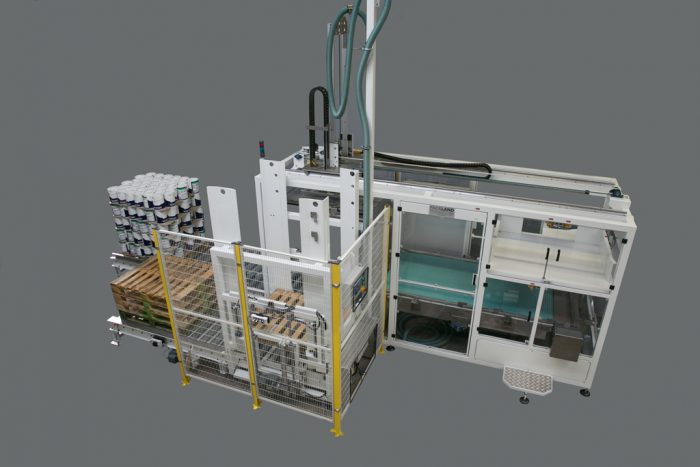

Packland can de-stacker

The Packland portal destacker destacks fully automatic cans of pallets, and stacks the emptied pallets. The cans and interleave sheets are picked up by vacuum. Sizes vary from 125mL (maximum 120/min) upto 6L (maximum 60/min). After adjusting the end guide and side guides and choosing the program on the HMI a new program can be run. The machine is available in different orientations, to allow for optimal accessibility in tight spaces.

A pallet filled with cans is placed on the infeed roller conveyor. From this position the pallet is fed into the depalletising position. At this position the cans are picked up by vacuum and placed on the buffer conveyor, from where the cans are fed into the filling machine. The interleaf sheets are placed in an interleaf magazine. Empty pallets are stacked and complete stacks are fed out of the machine.

- The pallet and can transport conveyors are driven by electrical motors.

- The movement of the portal is driven by servo motors, to allow for optimal precision and repeatability.

- Vacuum is created by a vacuumturbine.

- Machine comes complete with manual and CE marking.

- The machine is PLC controlled and equipped with a touch screen for operation and for displaying error messages.

- The touch screen features a USB connection for the download and upload of data.

- Also, the PLC has a connection for a TCP / IP connection. If required, we can send updates via this link.

- Changeover into another format is done by slides with rulers and program selection on the HMI. The changeover time is approximately 3 minutes, and done without tools.

Technical specifications:

| Machine speed | Maximum 120 cans per minute, depending on size |

| Container material | Ferrous, plastic. |

| Container dimensions | Cylindrical Minimal content: 125mL. Maximum content: 6L. Other sizes available on request. |

| Pallet sizes | CHEP or EURO, others sizes on request |

| Machine dimensions | ca 6500 x 3800 x 4600 mm (L x W x H) |

| Compressed air | 6 bar, clean dry air |

| Air consumption | approx 100L/m |

| Supply voltage | 400V – 3 phase / N / earth 50Hz, others on request |

Options:

- 90 degrees turned in/outfeed of pallets

- aditional buffer positions for filled/emptied pallets

- other wishes/requirements in consultation