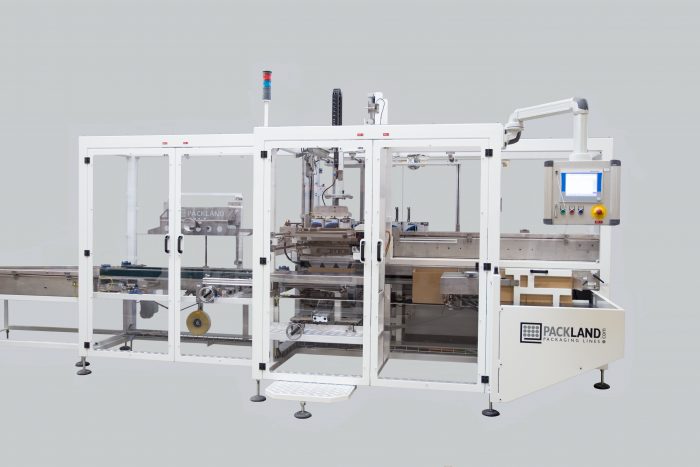

Packland PP6 / CE packaging machine

The fully automatic Packland Pick & Place PP6 / CE case packer packs tins, buckets, bottles, cans, boxes, etc. in American folding boxes.

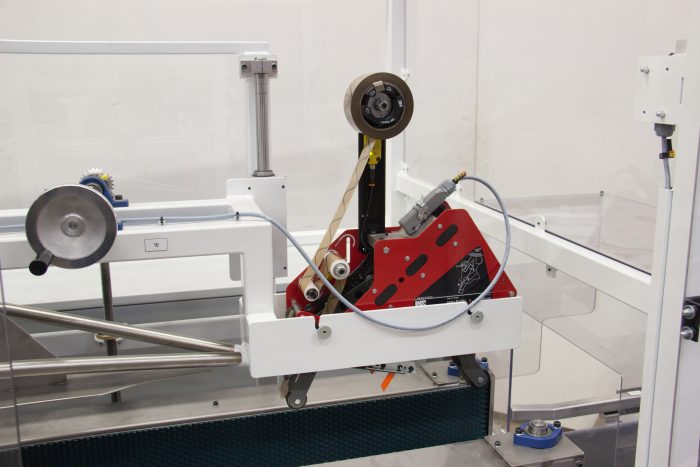

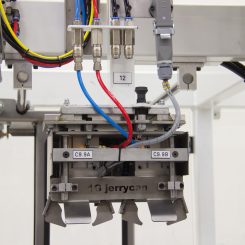

The containers are transported over an ascending conveyor. Then the machine puts them into the desired configuration, erects a box, places the containers in the box and closes the box with 50 mm wide self-adhesive tape.

- The product input and box output conveyors are driven by electric motors.

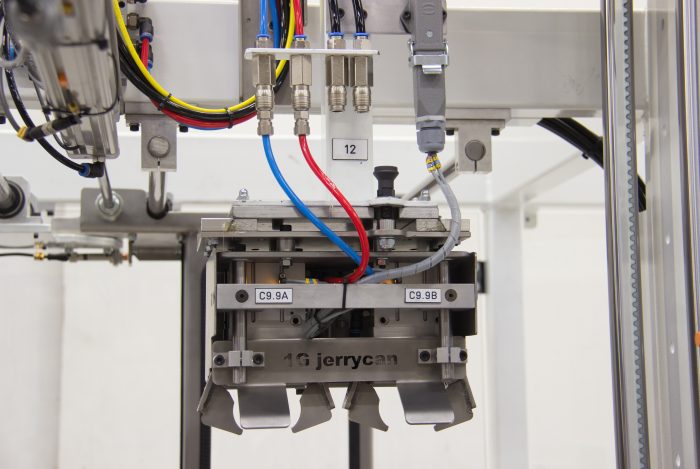

- The cardboard blank and the vertical product placer are servo driven for maximum precision and speed.

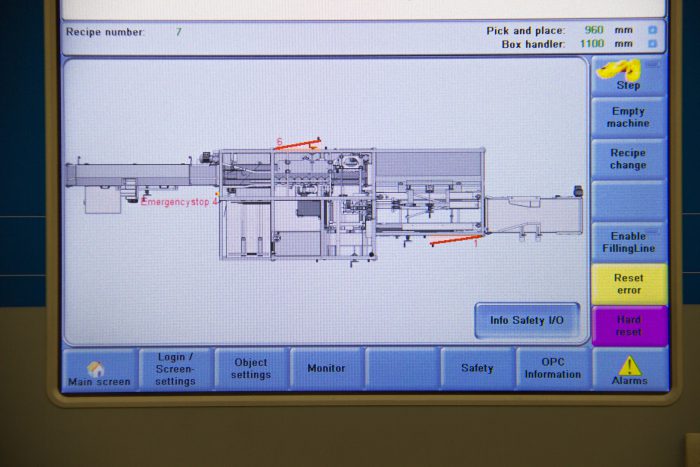

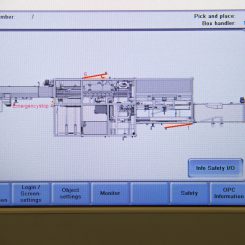

- The machine is PLC controlled and equipped with a touch screen for operation and for displaying error messages.

- The touch screen features a USB connection for the download and upload of data.

- Also, the PLC has a connection for a TCP / IP connection. If required, we can send updates via this link.

- Changeover into another format is carried out with 5 hand wheel with numeric counters and 3 change parts. The changeover time is approximately 5 minutes.

Technical specifications:

| Machine speed | Maximum 13 boxes per minute, depending on size |

| Container material | Ferrous, non-ferrous, plastic, glass, etc. |

| Container sizes | Cylindrical, conical, square or rectangular. With lid, cap, handle or strap. Minimum diameter / height: 60 x 60 mm. Maximum diameter / height: 260 x 280 mm. Other sizes available on request. |

| Box types | American folding boxes, American open top boxes |

| Box sizes | Minimum length / width / height: 180 x 110 x 66 mm. Maximum length / width / height: 500 x 420 x 290 mm. Other sizes available on request. |

| Machine dimensions | approx 4350 x 1900 x 2340 mm (L x W x H) without options |

| Compressed air | 6 bar, clean dry air |

| Air consumption | approx 400L/m |

| Supply voltage | 400V – 3 phase / N / earth 50Hz, others on request |

Options:

- left-right or right-left version

- orientator for aligning containers with a handle

- stacking of several layers in a box, with optional second filling station

- placing an divider sheet between the layers

- packing in open top boxes

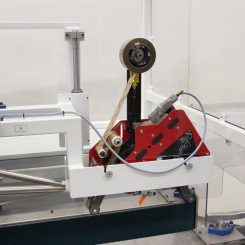

- tape dispenser for adhesive tape with a width of 75 mm

- detection of tape length, tape cut and nearly out of tape

- bypass for products that do not have to be packaged

- lid check with rejection band

- change part rack

- other wishes/requirements in consultation